Customer Services

Copyright © 2025 Desertcart Holdings Limited

🎨 Elevate your concrete game—because your floors deserve to be as bold as your vision.

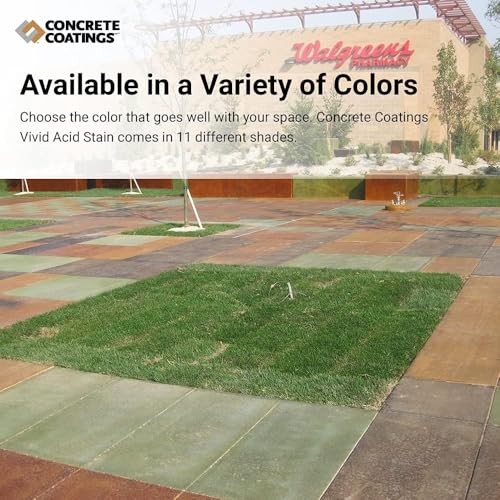

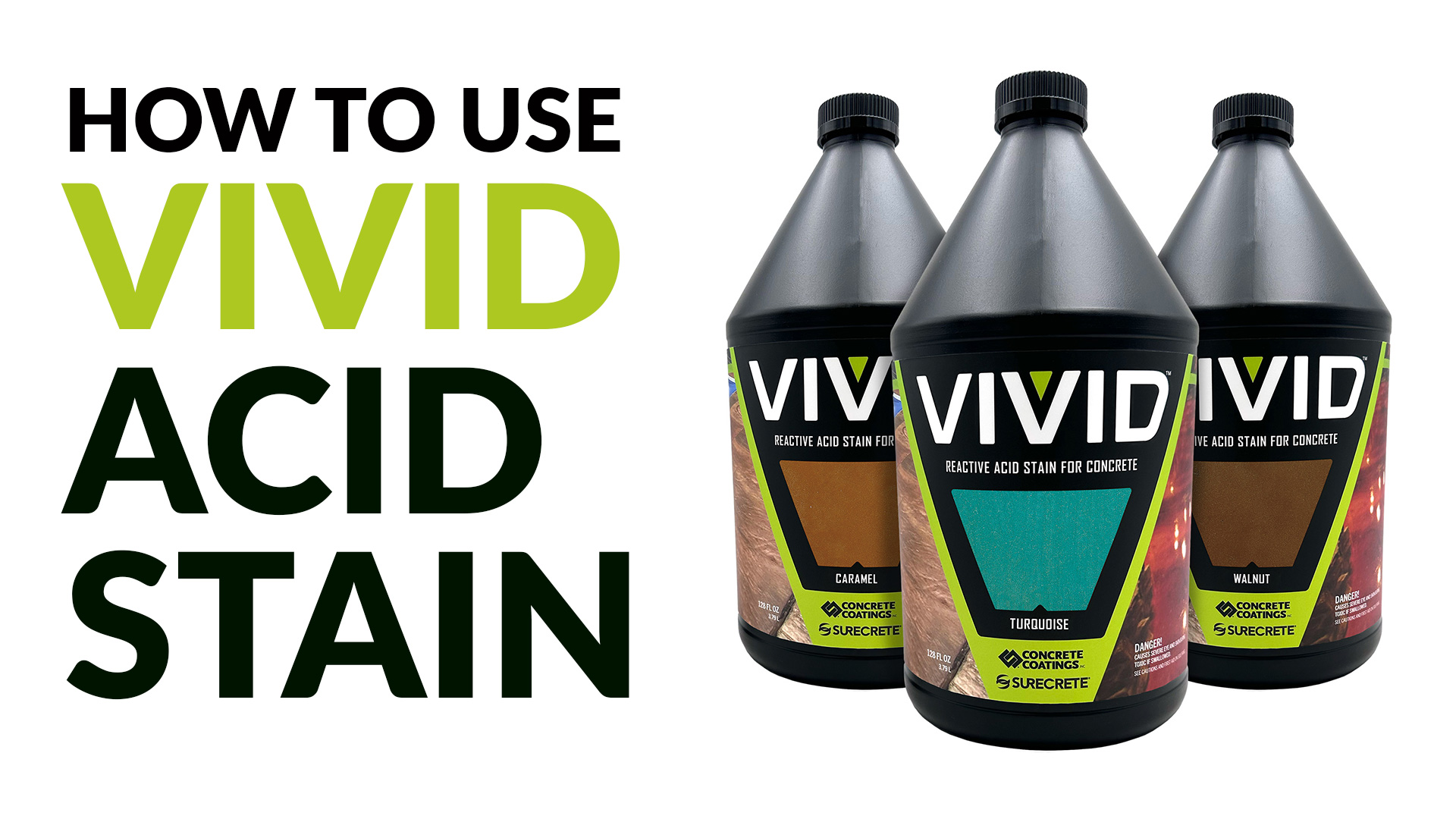

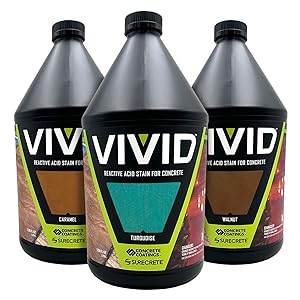

CC Concrete Coatings Vivid Acid Stain in Olive is a 4 oz tester acid stain designed to chemically penetrate and react with concrete surfaces, creating a durable, variegated, and textured finish. Ideal for both interior and exterior projects, it covers approximately 8 sq. ft. per coat and offers a unique faux-marble aesthetic that transforms ordinary concrete into a statement piece. Perfect for professionals and DIYers who value precision, durability, and artistic flair in their concrete coatings.

| ASIN | B00EEHXOHQ |

| Batteries Included? | No |

| Batteries Required? | No |

| Best Sellers Rank | #54,463 in Tools & Home Improvement ( See Top 100 in Tools & Home Improvement ) #81 in Household Stains |

| Brand | CC Concrete Coatings |

| Coating Description | Acid stain for concrete, penetrates and reacts with the surface to create a permanent, mottled color. |

| Color | Olive |

| Coverage | Approximately 8 sq. ft. per application, per coat |

| Customer Reviews | 4.0 4.0 out of 5 stars (2,873) |

| Date First Available | September 15, 2015 |

| Finish | Textured |

| Finish Type | Textured |

| Included Components | Bag |

| Item Package Quantity | 1 |

| Item Weight | 4 ounces |

| Item dimensions L x W x H | 6 x 6 x 12 inches |

| Item model number | CS-900-4oz |

| Liquid Volume | 4 Fluid Ounces |

| Manufacturer | CC Concrete Coatings |

| Material | Stain |

| Model Name | CS-900-4oz |

| Number of Items | 1 |

| Package Information | Bottle |

| Paint Type | Acid Stain |

| Part Number | CS-900-4oz |

| Product Dimensions | 6 x 6 x 12 inches |

| Recommended Uses For Product | exterior-and-interior |

| Size | 4 Ounce Tester |

| Special Feature | Variegated Color |

| Special Features | Variegated Color |

| Style | Rustic |

| Surface Recommendation | Concrete |

| UPC | 852664446713 |

| Unit Count | 4 Ounce |

G**K

A GREAT PRODUCT..... DO YOUR HOMEWORK, AND PREP CAREFULLY.

Okay.....bear with me. The sales pictures of the results using this type of concrete stain are captivating, to say the least. I am no klutz, and have built and stained/finished high end furniture for over 30 years for a living. I understand materials and their application. WOW, who wouldn't want that "faux Marble" look that is shown when this stain is applied properly. For a couple hundred $$, you can have a million dollar floor, driveway, patio, or pool surround. We used it on a 25 X 30, NEW kitchen floor.....yeah, that IS a big kitchen. We process hundreds of pounds of vegetables, fruit, and butcher multiple deer, hogs, goats and chickens throughout a normal year....we milk a Guernsey and several Dexters and make 4 lbs of cheese a day. We wanted a DURABLE, WASHABLE, ATTRACTIVE floor. We chose "Coffee" because it mimicked the dirt color around here the best. I am going to try and write this to "add" to the Instructions and TDS, (Technical Data Sheets), that are available on the product. Most of the questions I ask, or information I pass on are "extra" to the actual application of the stain....THEY ARE CRITICAL FOR A QUALITY COMPLETION OF A PROJECT USING THIS STAIN. 1) READ THE INSTRUCTIONS.......... MULTIPLE TIMES. 2) READ THE INSTRUCTIONS AND TDS SHEETS.......MULTIPLE TIMES. 3) READ THE INSTRUCTIONS, AND WHILE YOU ARE READING THEM, RUN A COUPLE OF THE VIDEOS ON YOUTUBE SO THAT YOU CAN GET "ORIENTED" AS TO VARIOUS APPLICATION METHODS. 4) SO YOU DON'T FORGET ANYTHING....READ THE INSTRUCTIONS AGAIN. 5) GET THE COMPANY'S TECHNICAL SUPPORT PHONE NUMBER WHERE YOU CAN HAVE IT READILY AVAILABLE. 6) CONSIDER THESE QUESTIONS THAT THE MANUFACTURER DOES NOT ASK, OR ONLY TOUCHES ON VERY SUPERFICIALLY A) What is your concrete made of.....Ha,HA you laugh....it's made of gravel, sand and Portland Cement, Well, the only thing that concrete in various parts of the country have in common is Portland Cement. Sand and gravel will vary from city to city. Here in NW Arkansas, we have concrete plants on a creek or river that use washed and graded creek gravel and sand for their mix. 30 miles away, we have concrete plants that are far from a creek....but close to a lot of quarry-able limestone. They crush and grade limestone, and use it for both "gravel" and "sand". WOW, does that make some VERY strong concrete.....BUT....it is a completely different beast from smooth, washed creek gravel and sand. IT IS VERY HIGH IN REACTIVE CARBONATES....AND MAGNESIUM.... The creek mix is FAR,FAR less reactive to the stain. Can you find out the source and ask them what mix they used, or usually use when supplying a project in your area. B) How well is your concrete finished ??? How "tight" is the surface. Who was the finisher, and what does he remember about the mix and the pour. There are vast differences in texture and composition between lightly troweled and heavily troweled concrete. C) CONSIDER BUYING the stain sample kit sold by the company....BUT, one caveat. When we send out color samples to furniture customers, we stress over and over again that it is nearly impossible to get an accurate vision of a completed piece's color from a small, hand held, sample. We did not get the kit. We picked a color and understood that, good-or-bad, we would be "stuck" with the color it yielded on our floor. You may have a VERY,VERY easy go of it, and everything might fall into place with what you have to work with. BUT IF IT DOESN'T....can you live with less-than-expected results ?? D) How long has the concrete been in place??? Inside, or outside like a driveway/sidewalk/pool surround??? If it is outside.....and is older than 1 or 2 months, HOW ACIDIC is your rain??? Acid is the bane of this finish. It is really not a stain, but a reactive acid/chemical. The longer your concrete is in acidic rain, the less reactive the mix will be. TREATED LUMBER is treated with an acidic, metal mix. If you were to stain a slab that had been in place under an elevated, treated lumber deck that was open to the rain.....you would get the " ghosts " of the boards where the rain dripped off the deck, down onto the concrete. The reactivity of the concrete will depend on an interaction of these elements. After you have a general understanding of what you have to work with, you can begin to gauge how the stain will react, and guess how you should proceed. I did all the research I could, and read the directions and TDS sheets over and over....I watched all the YouTube videos.. I gave this stain a 5 STAR rating. It is fabulous. The company is excellent and responsive to questions. This stain is 2X better than what the Big Box, do-it-yourself stores will sell you. GO WITH VIVID....it is a great product.........HOWEVER....BE WARNED......My completed job was about a 3 STAR from what we " expected ". By the time I do my 3rd floor....I'll know all the ins-and-outs and what to look for. We followed all the directions....researched all the glitches......planned for the unexpected....but this is a totally different process, with its own set of rules. Here is a brief summary of our results. We picked coffee....."brown with a slight red hue"..... I used 2.5 gallons on 700 sq ft and there is not a hint of brown, let alone red. It is "black coffee" black. In fact, it is "espresso" black, with the mottling being various shades of gray. I will cut the stain by 1/3.....or maybe 1/2 and go with 2 applications if necessary in the future. We used it full strength. Our concrete was finished by " professionals", but rural Arkansas professionals.....the surface varied in tightness, and the stain took dramatically different on each gradient of "smoothness". It "fizzed" very heavily on some sections, and not-so-much on others. Our concrete is crushed limestone.....very high in Magnesium ( the black we experienced ???). Our slab has a 3" in 30 ft slope toward the back door to facilitate washing the floor and squeegee-ing the water out the door. If a slab is not perfectly level, you will have to be prepared to even out any material that tends to "run" and pool up along the lower part of the spray line. I will have some sort of sponge mop ready to spread the excess in a more even coating. A set of treated lumber stairs ( the slab was completed a year prior to erecting the room over it) left a "ghost" impression in the floor. NO PROBLEM, we are going to brick up a set of stairs on that spot....but do take note of that. My floor was dark, far darker and blacker than we were expecting. I have an 18" industrial buffer and we prepped the floor with a lot of TSP and GREEN pad scrubbing. After staining, we actually used a less abrasive RED pad to try and bump down the color. It did help, and it evened the color out somewhat. I want the marbled effect....but we had from near jet-black to medium gray. I used one coat of SUPER SEAL 20WB. Great product. About 2 gallons sealed the floor. We will do the rest of the electric, hang the sheetrock, do the brickwork and then scrub and seal with a second coat before waxing. Don't get me wrong....the floor is attractive. More so than a slab or a painted slab. We did not achieve the spectacular results that we saw in the "pictures". And, the color was completely different from what we expected. However, notice I didn't say "were led to believe". The company makes it plain as day that there are many, many variables that affect the results. I hope this prompts some to look for more variables, and prepare to adjust the application. A GREAT PRODUCT..... DO YOUR HOMEWORK, AND PREP CAREFULLY.

M**C

Easier to use than you think!

I have now used this stain on three different concrete pads and it's awesome. The first time I used it, I followed the directions to the letter. Lightly wet the concrete then spray the acid with a clean bug sprayer (a pain when it's 75 degrees and sunny and the water evaporates faster than you can spray)... wait a few hours... neutralize the acid with a mixture of ammonia and water... scrub the black residue that comes up during the reaction... clean the concrete.... wait a day or two, then seal it. The color came out great. Looked a little dull like the last photo in this review, but once I sealed it, it looks more like the second to last photo (I did not use a wet-look seal so it doesn't look AS shiny.) The second time I used it, it happened to snow within about an hour of me finishing the spraying. Unable to neutralize the acid, I figured it would just come out darker since it would be sitting on the concrete for longer. It came out THE SAME. After the snow, it rained a little here and there and with the water melting off the concrete and a little rain hitting it, the black residue came off completely on it's own. This saved my back since I didn't have to bug spray the whole thing a second time with the ammonia or manually scrub off the black on my hands and knees. We like a rich orange/rust color so I was happy that the final color is exactly the same as our first pad (the two seconds of concrete touch each other so I was hoping it would come out very similar in color). The THIRD time we've used this acid stain are the photos I've posted here. This time, I was going to work smarter - not harder. It had rained prior to me applying the acid so the pad was already wet. It ended up being a little too wet and when I sprayed, the acid flowed into a couple low spots and pooled, you can kind of see where that happened. For our use, this doesn't bother me. But if you want an even color, make sure your pad doesn't have any spots where there is pooled water. I sprayed the acid and just left it. The first photo is about four hours after I sprayed it (it rained on and off all day). The black residue basically covered the entire pad. I wet the concrete with the hose and tried to scrub it with a shop broom but I was convinced it was stuck on there. When the pad completely dried out, that is the second photo with some white crusty residue. So I decided to wet the pad again (the third photo) to show me how much black residue was left. There wasn't much, so I decided to give it just a little pass over with a shop broom while wet and let it dry out again to see if more came off. It ended up raining the rest of the day and POOF the fourth picture is what I found a few hours later! The fifth picture I just took and is how the pad looks with no sealer and no moisture. Looks dusty but I promise it will have a rich color more like the fourth picture when I put the sealer on. I should have just let the rain wash away the black residue and saved myself some vigorous scrubbing but I doubted myself for a minute. Sorry for this hugely long review but essentially what I'm trying to say is this stuff is WAY easier to use and way harder to mess up than you think!! Just some regular watering after acid staining will save you a lot of trouble.

A**R

Would not recommend It did not stain the concrete or adhere to concrete Solution watery No refund offered therefore waste of money Product did not work!

Trustpilot

1 day ago

2 weeks ago