Customer Services

Copyright © 2025 Desertcart Holdings Limited

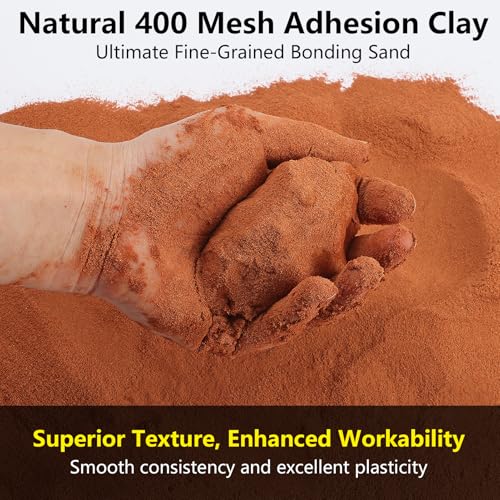

⚡️ Elevate your metal casting game with ultra-fine precision and sustainable style!

Holama’s Ultra-Fine 400 Mesh Oil-Free Casting Sand delivers exceptional detail reproduction for professional jewelry and metal casting. Compatible with a wide range of metals, this premium, reusable foundry sand offers superior mold stability and smooth finishes, empowering skilled artisans to create intricate, museum-quality replicas while embracing eco-friendly practices.

| ASIN | B0D9YX9DXJ |

| Best Sellers Rank | 1,457,990 in Home & Kitchen ( See Top 100 in Home & Kitchen ) 4,834 in Sculpting Moulding & Casting |

| Brand | holama |

| Colour | Red - 10 Pounds |

| Customer Reviews | 4.4 4.4 out of 5 stars (74) |

| Date First Available | 17 Sept. 2024 |

| Item Weight | 4.54 kg |

| Material | Clay |

| Model Number | Casting Sand-5/10lbs |

| Product Dimensions | 24.89 x 24.89 x 7.62 cm; 4.54 kg |

B**I

Been experimenting with this casting sand for about three weeks now doing some small metal projects in my workshop. The 400 mesh fineness is noticeably finer than other sands I’ve used - when you run it through your fingers it feels almost silky smooth. The detail reproduction is impressive once you get the mix right, I cast a couple small medallions and the surface came out smooth with crisp edges. The fine grain really does capture intricate patterns well. Now they aren’t kidding when they say this is for experienced users. Getting the right ratio of binders and water took me several attempts. Too wet and the mold won’t hold shape, too dry and it crumbles when you pull the pattern. I wasted probably my first 5-6 attempts before dialing in the consistency that worked. The instructions that came with it were pretty minimal so expect to do some trial and error or research on your own. I’ve used it successfully with pewter and aluminum so far, both cast nicely once I figured out the moisture content. The sand does pack well into the flask and releases from patterns cleanly when mixed properly. Reusability is good - I’ve recycled the same batch multiple times just reconditioning it with a little water between uses. One thing to watch is making sure the mold is completely dry before pouring, any residual moisture causes problems. The sand stores fine in a sealed bucket between sessions. For hobbyists already familiar with sand casting this is quality material at a reasonable price, but complete beginners might want to start with a more forgiving premixed option first.

H**E

In addition to a coin-like disk with a defined border, I pressed in a signet-face master that has a clear outside boundary. I also pressed in a pendant blank that has raised line work. When I cut the mold in half, the cavities did not get corrupted, and the impressions came out looking quite similar to the originals rather than softened. It is essential that the cavities be stable at this size since a little rip or collapse will frequently strike exactly where the detail is most evident, and repairing it will typically require starting from scratch. As I proceeded, I saw that the uniformity remained consistent over the many sessions. My goal was to get a mold quality that was comparable on several days, and I was successful in doing so by applying consistent packing pressure and paying great attention to alignment. When the completed item was done, the line work on the pendant pattern remained obvious enough that it required minimal corrective shaping. Similarly, the border on the disk pattern remained defined rather than becoming a rounded suggestion. The standard cleaning process is still something I anticipate doing on each cast item; however, I spent less time fixing faults that might have been avoided and that resulted from a damaged mold surface. This is precisely what I desire when I am attempting to build a matching pair or a tiny set, since when I repeated the same procedure in a later session, the output had a tight relationship with my previous efforts.

C**Y

When working on items like pendants, charms, or ornamental accessories, pressing a model into the sand helps to maintain even the tiniest of textures and tiny lines. This has a significant impact on the final product. My time spent on post-casting cleaning and polishing is reduced since the metal pieces that are produced as a consequence of casting have a low amount of surface imperfections. I was able to complete tasks more quickly while still achieving the level of quality that I strive for because of the efficiency that I have achieved. The fact that the sand does not contain any oil has also been a significant advantage. Although it does not leave a greasy residue on molds or tools, it has a cleaner feel when it is being worked with. When moving between various metals during the same session, this makes preparation and cleaning considerably easier. This is particularly true when transitioning between steels. This casting media is also simpler to handle for extended periods of time without feeling heavy or clumpy, which is a problem that may occur with other casting mediums.

K**R

Item recieved in great condition.

V**N

As a beginner for sand casting I would not recommend. This product seems like it would work for someone who’s already experienced with sand casting. There are no instructions provided and you’re supposed to guess the water to sand ratio to find the appropriate binding consistency. Personally I could not figure it out despite working in small batches until I used up the entire bag of sand. Once the sand was packed, the wax carving would not sink to imprint and I was concerned it would break trying to press it down so hard. When I finally got the wax carving in the clay it came lose and crumbled despite packing it tight in the aluminum tin.

Trustpilot

5 days ago

1 week ago