Customer Services

Copyright © 2025 Desertcart Holdings Limited

💎 Polish Like a Pro, Shine Like a Boss

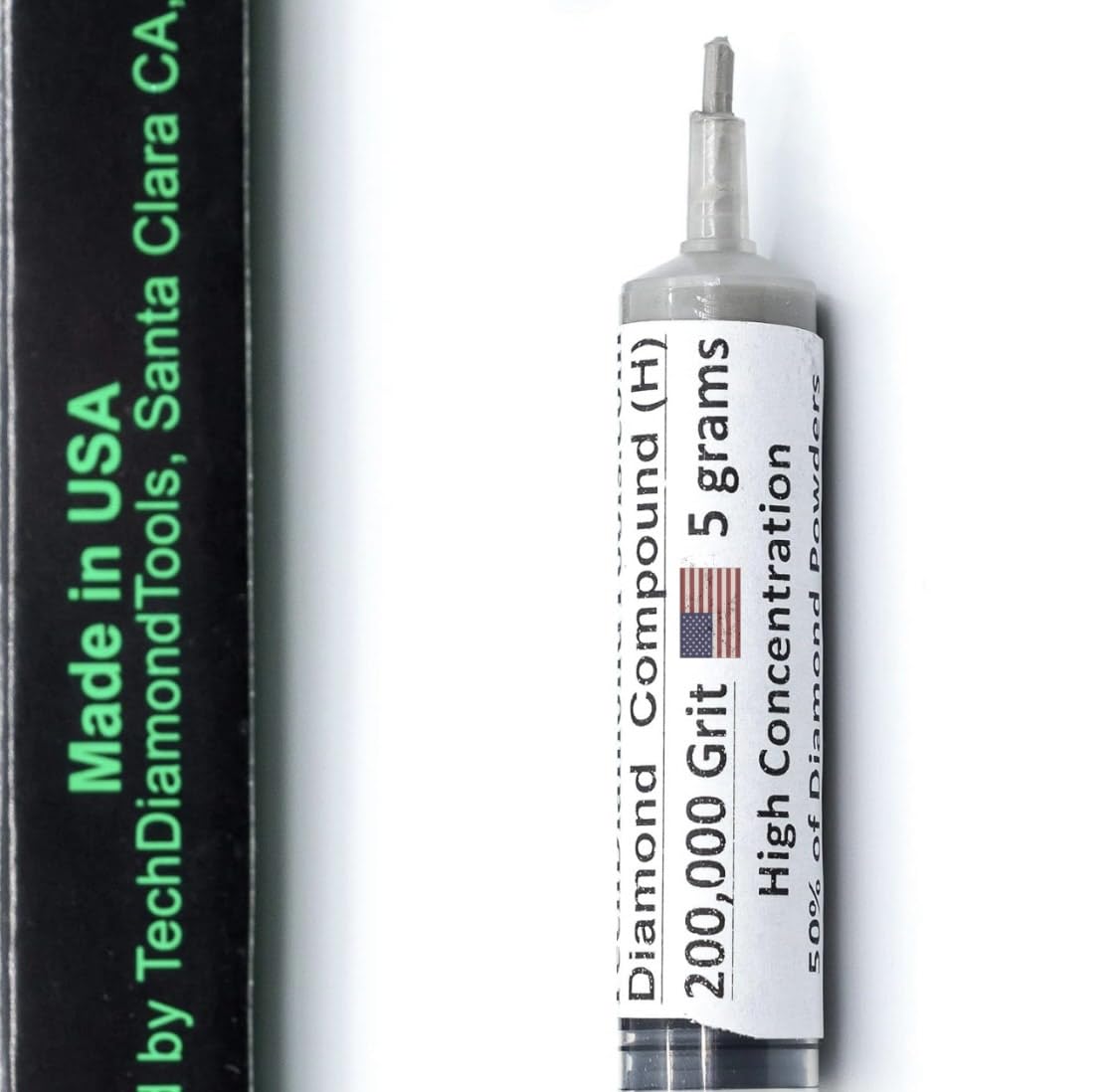

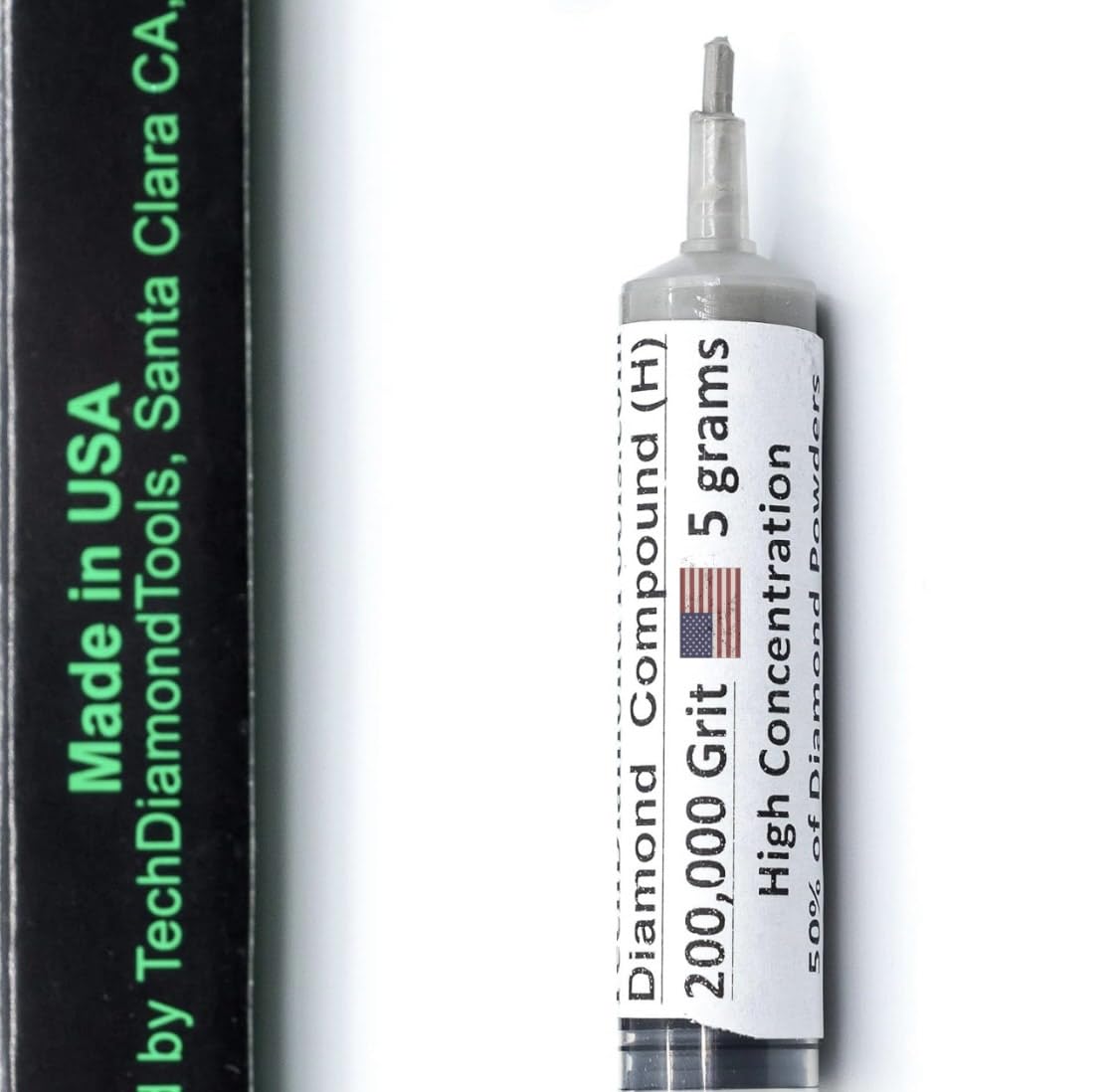

TechDiamondTools Diamond Polishing Compound is a premium, USA-made, oil-based paste featuring an ultra-fine 200,000 grit (0-0.1 microns) with 50% diamond powder concentration. Engineered for industrial and DIY use, it delivers rapid, precise polishing and scratch removal on metals, glass, ceramics, gemstones, and composites. Compatible with manual and machine polishing, it’s the go-to solution for professionals and hobbyists seeking mirror-quality finishes across a wide range of materials.

| ASIN | B00I5B1JY2 |

| Best Sellers Rank | #4,488 in Industrial & Scientific ( See Top 100 in Industrial & Scientific ) #3 in Abrasive Finishing Compounds |

| Brand | TechDiamondTools |

| Date First Available | July 22, 2012 |

| Grit Material | Diamond |

| Grit Type | Extra Fine |

| Is Discontinued By Manufacturer | No |

| Item Weight | 0.16 ounces |

| Item dimensions L x W x H | 7 x 4 x 0.75 inches |

| Item model number | DP-200H |

| Manufacturer | TechDiamondTools |

| Material | Diamond |

| Product Dimensions | 7 x 4 x 0.75 inches |

| UPC | 818510013683 |

C**O

THE REAL DEAL DIAMOND PASTE!

After months of trying to find a true working diamond paste, I finally decided to try TechDiamondTools. The pricing was great and quite frankly the cheap diamond paste was just not working for me (yeah...i tried to go cheap). I've been trying to find a reliable way to get scratches out of mineral glass and most internet searches claimed it was very difficult. Not only could I not find a guide to do this, but couldn't find a grit guide to use for mineral glass. The first thing I did was message the TechDiamondTools and asked for guidance. They replied to me several times and have been very courteous and helpful. They recommended several grits to try, so I went ahead and ordered. Here is what I used, and it works GREAT! Just be patient (this is the key to perfection). Rotary Tool (Cheap) I also used an adjustable speed control rotary tool with 3/32 pro bits compatible that is used for nail manicures. It's electric. I did a search on Amazon and the no longer sell it, but Pinkiou looks similar and it's cheap. I don't recommend using a high speed Dremel. I have one and it goes way to fast. I started with 600, then 1,500, 3,000, and finally 5,000 grit. The results were amazing! Now to keep things in perspective, I did mess up and used sandpaper on one of my other watches. Used 100 grit and that was a mistake. The pictures I posted, I didn't use sandpaper. On the other watch, it did get all the scratches the sandpaper made, however it took a bit more of time. Next time I'm using 2,000/1,500 grit sandpaper. I've read that's what should be used before using diamond paste. I currently have a 14,000 grit that I can't decide whether to use for polishing since the 5,000 did a superb job. I may just return that 14,000 and use the 8,000 for final polishing. Okay, back to the watch. the pictures are the result so the diamond paste. I "wish" that I had a picture of the watch before I even started, but I totally forgot to take some. The pictures are after I had already gone through using the 600 grit and the 1500 grit. As you can see the scratches I circled. Trust me before I started, these scratches were pretty bad. You could actually catch you fingernail on it. Not just a hairline scratch either. The final picture is the finished product, although it looks superb and flawless, I wonder what a final polish with 8,000 or 14,000 would do. I haven't tried that yet. Anyway, I am very pleased with DiamondTechTools, they actually worked with me to replace the 400 grit because it seemed watered down, but they made it right. As a hobby I work on Casio's digital watches and refurbish them, and the biggest problem with refurbishing is the scratches on the glass. Well to end this, I'd like to say I did order the 400 grit paste and will start with that to see if it cuts back on my time. The pictures of the watch I posted took me about 3 hours to get the scratches out, I'm hoping with 400 grit, I'm able to cut that time in half. I don't like to used sand paper, but I will if there are a lot of bad scratches, then I will. Just don't use 100 grit like I did. Use 2,000 or 1,500. I'd also like to say, if you use this process, your result may vary. I want to say that because I'm a very meticulous person and I take my time. I'm only putting this out because this actually worked for me after all failed attempts with other diamond paste, and no I didn't get any free products from TechDiamondTools. If Amazon lets me, since I ordered like 6 syringes of different grits, I want to post more pictures of scratched up watches and the results. Hope this helps folks out there that have not found any documents on getting scratches out of mineral glass, because there really isn't any clear document that outline this. Hope this help those watch enthusiast out there!! And thank you DiamondTechTools, ya'll are awesome and keep making those American Products GREAT!!!

J**E

Smooth Finish, Impressive Results

This 3,000 grit diamond polishing compound completely exceeded my expectations. I’ve been using it on a variety of surfaces—marble, metal, and even a couple of resin pendants I cast recently—and the results are consistently excellent. The paste has a nice consistency that's easy to spread evenly, and it doesn’t dry out or gum up like some cheaper compounds I’ve tried before. What really impressed me is how high the concentration of diamond powder feels. It’s aggressive enough to make a noticeable difference quickly but still refined enough to give a smooth, glassy finish. I used just a dab on a felt wheel and brought a dull piece of silver back to a mirror shine. Same with a glass cabochon—it went from cloudy to crystal-clear in minutes. It’s also nice knowing it’s made in the USA. There’s a sense of quality control here that shows up in how reliable and consistent it is across different jobs. Whether I’m polishing jewelry or sharpening chisels, this compound gets the job done cleanly and quickly. A little goes a long way, so it's also a good value. I'll definitely be keeping a jar of this on hand in my shop.

M**E

Be patient, thorough and get AWESOME results!

Fantastic product that delivers great results. You have to be patient and willing to go through a process, but it’s well worth it. I did several applications of the diamond paste. First two applications, I took small dabs of past on my finger, and pushed them into the scratches, filling them in and then taking a wet q-tip to gently, with slight pressure, massaging the paste around in a circular motion. After those first two applications, I already noticed the scratches becoming more dull and unnoticeable. The last three applications, I cut a plush microfiber cloth into 1” x 1” squares and applied the paste directly onto them. I dampened them with a bit of water and and again massaged the paste around the watch face, with slightly more pressure and faster motion. Conclusion: Deep scratches gone and a restored watch face. I think it looks better than it did before. Thank you.

A**C

Leaves a beautiful finish with just a tiny amount

I make rings and other small metal works, and I often put the final polish on them by hand or using a lathe. For a long time, I was using just the solid polishing bars - and while they work well, I have difficulty repeating results, it's always a little trial and error. I purchased this to test as an alternative. I am quite happy with it. Just a tiny amount - the size of a grain of rice - is enough to polish a surface about 2" in diameter, and probably larger. It spreads very easily by hand and can be polished similarly easily. I noticed that unlike many other polishing compounds, you can hardly feel the grit in this one at all - it's that fine. I put a final mirror finish on a copper alloy disk (after initial work had been done) in about three minutes by hand using this paste. It's the first time I've used a syringe to apply polishing compound and found it quite easy to control. I found that it didn't really work on aluminum or resin, which I found disappointing. It is possible they were both too soft for this kind of compound, I couldn't really get the ultra-smooth reflective surface I wanted out of them, even after a subsequent waxing. On copper and bronze, though, it works beautifully.

N**T

This paste (14,000 grit) does wonder to my straight edge razor after the 10,000 grit stone (using flat leather strop). I might still get the 50,000 grit to get a perfect edge, but it's already close to being "as new".

A**L

For i phone screen

J**N

The fact that this is 50% diamond grit, means that you use less, and get the job done quicker, which means that this is a brilliant product, which is likely to work out cheaper in the long run, especially if you are comparing it to the products that are only 5% to 10% diamond grit. And, I would’ve shown you how much it works with an opal that I spent just twenty minutes polishing, but I was unable to upload the pictures and video, because I refused to allow amazon access to my whole collection of pictures and videos.

M**O

ottimo

L**C

Je ne doute pas de la qualité du produit en tant que tel mais la seringue qui contient la pâte est arrivée dans un état lamentable (voir photo) ce qui veut dire que si je n'utilise pas tout il va falloir que je trouve un autre contenant, c'est pas gagné...

Trustpilot

1 month ago

2 weeks ago